Recommended maximum space between hangers for straight horizontal pipes and tubes are indicated in the table below.

Span pipe support spacing table standards.

Based on mss table 3 4 based on astm a53 86 many codes require pipe hangers to be spaced every 10 ft.

If supports are spaced greater than 25 0 consultation with a structural engineer should be performed for additional analysis.

Add standard and customized parametric components like flange beams lumbers piping stairs and more.

Support span table from asme b 31 1 v.

Regardless of 1 cubic ft.

2 7 0 2143 2 6 9 25 1622 3 7 10 0 1500 4 8 10 0 1500 5 calculated 11 0 1364 figure 2.

1 gallon u s weighs 8 335 lbs.

Table 11 a maximum loads for tubular support feet 21 table 11 b maximum loads for sectional support feet 24 table 12 maximum vertical loads on cantilevers of various sections 34 table 13 maximum permissible single span simply supported universal beams when loaded at b 4 from toe of flange 38.

Pipe support span chart.

The values does not apply where loads are concentrated with flanges valves specialties etc.

3 pipe support span chart from mss sp 69 is reproduced as a sample.

A common rule of thumb is to support loads of this type with hangers on both sides of the load.

1 ft foot 0 3048 m.

Spans are also provided for pipe deflection of 25 mm for all pipe sizes.

Pipe support spacing table chart for carbon steel pipes.

References values of maximum span for ss pipe 300 nps filled with water meters no.

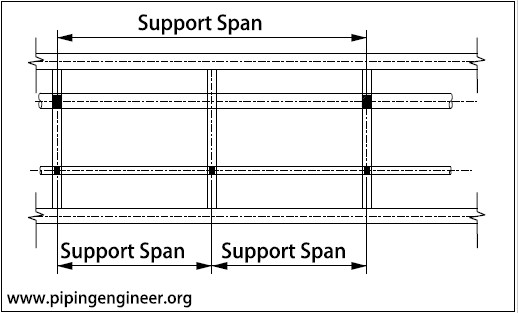

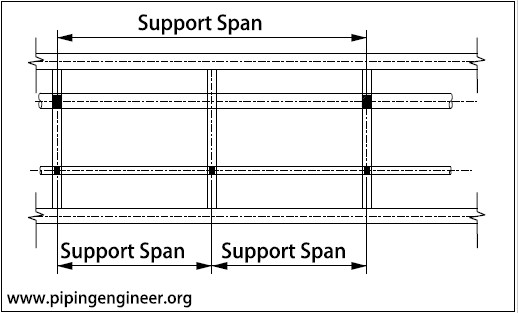

Hanger support spacing rod sizes horizontal pipes recommended maximum support span between hangers and rod sizes for straight horizontal pipes.

Ductwork ducts support spacing hangers distance.

These charts are normally mentioned in piping stress analysis project specifications.

Spans are based on 12 1 2 mill tolerance and 065 correction tolerance.

As a rule of thumb the spacing of pipe supports for steel pipes in liquid service expressed in feet may be taken as the nominal pipe size expressed in inches plus ten.

Table 1 comparative values of span sr.

Spans are based on using carbon steel pipe a53 gr b filled with water.

Spans are based on insulated and uninsulated lines below 650 f.

In the following image fig.

Spans or support spacing are based on maximum pipe deflections of 6 35 mm up to 6 and 12 7 mm for pipe sizes 8 and above.

It is based on a maximum bending stress of 2300 psi and maximum sag at mid span of 0 10.

Pipe support span chart is a tabular chart giving a rough idea of supporting distance.

Of supports required for a pipeline across 15 km 1 fig.

In practice longer spans are usually feasible with a deadweight bending stress in the order of 5000 psi to 10 000 psi.

Of water weighs 62 41 lbs.